What is the difference between a full-servo sanitary napkin making machine and a semi-servo sanitary napkin making machine?

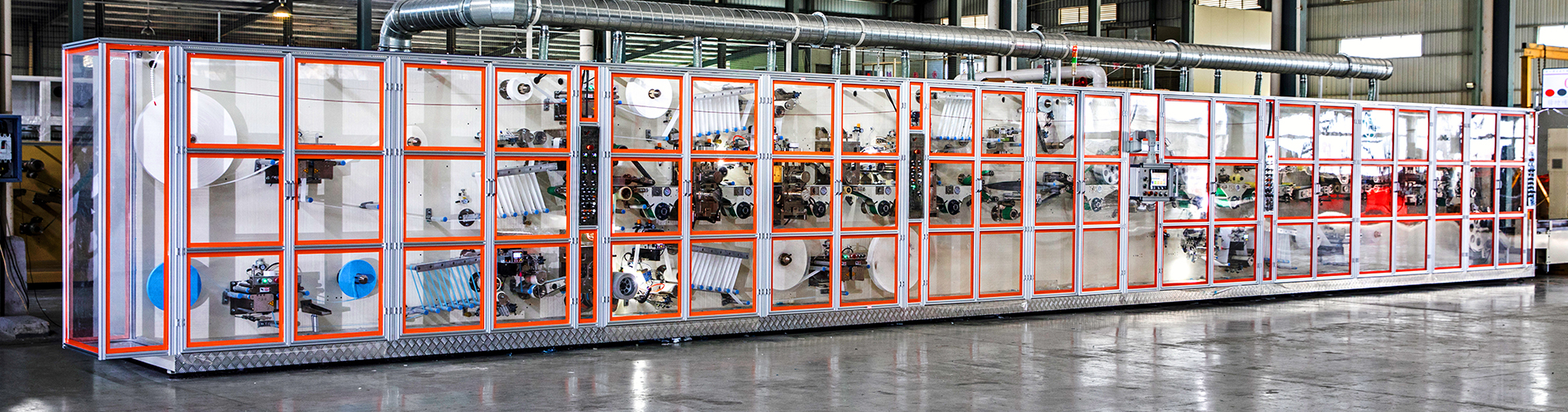

A fully servo-driven sanitary pad manufacturing machine utilizes a complete electric servo system to drive various components, including the feeding system, cutting system, folding system, etc. Through precise electronic control, it enables a highly automated and precise production process.

A semi-servo-driven sanitary pad manufacturing machine typically adopts a servo system to drive key components such as the feeding system or cutting system, while other components may be driven by traditional mechanical mechanisms. This hybrid driving method combines both electric and mechanical operations.

Fully Servo System

High precision and stability: The full servo system can provide higher precision and stability, ensuring consistent product quality.

Adjustability and flexibility: The full servo system allows for quick adjustments and changes in production requirements through electronic control, enhancing production flexibility.

High level of automation: The full servo system enables a highly automated production process, reducing manual operations and labor costs.

Semi-Servo System

Lower cost: Compared to the full servo system, the semi-servo system typically has lower costs, making it more suitable for budget-constrained production environments.

Simplified operation and maintenance: The use of partially mechanically driven components simplifies operation and maintenance, reducing technical requirements and maintenance costs.

Fully Servo System

Higher cost: The full servo system generally comes with higher costs, including equipment prices, maintenance, and repair costs.

Higher technical requirements: Operating and maintaining a full servo system requires relatively higher technical skills and expertise.

Semi-Servo System

Lower precision and stability: Compared to the full servo system, the semi-servo system may have lower precision and stability, which could have some impact on product quality and consistency.

Limited flexibility: Due to the use of mechanical-driven components, the semi-servo system may have limitations in terms of flexibility compared to the full servo system.

A fully servo-driven sanitary pad manufacturing machine offers higher precision, stability, and automation but comes with higher costs and technical requirements.

A semi-servo-driven sanitary pad manufacturing machine has lower costs and simplified operation and maintenance but may sacrifice some precision and flexibility.

When selecting a sanitary pad manufacturing machine, it is important to consider the actual requirements and budget to choose the appropriate machine model that meets production needs. Get more sanitary pad machine from https://www.dnw-machine.com

Categories

Latest blog

© Copyright: QuanZhou XingYuan Machinery Manufacture Co.,Ltd All Rights Reserved.

IPv6 network supported