What Is a Diaper Machine and How Does It Work?

In the hygiene product manufacturing industry, a diaper machine—also referred to as a diaper production machine—is a specialized piece of equipment designed to automate the entire process of creating disposable diapers, including baby diapers, adult diapers, and related hygiene products. These machines are the backbone of efficient production lines, enabling manufacturers to meet the high global demand for reliable, high-quality diapers while maintaining consistency and reducing labor costs.

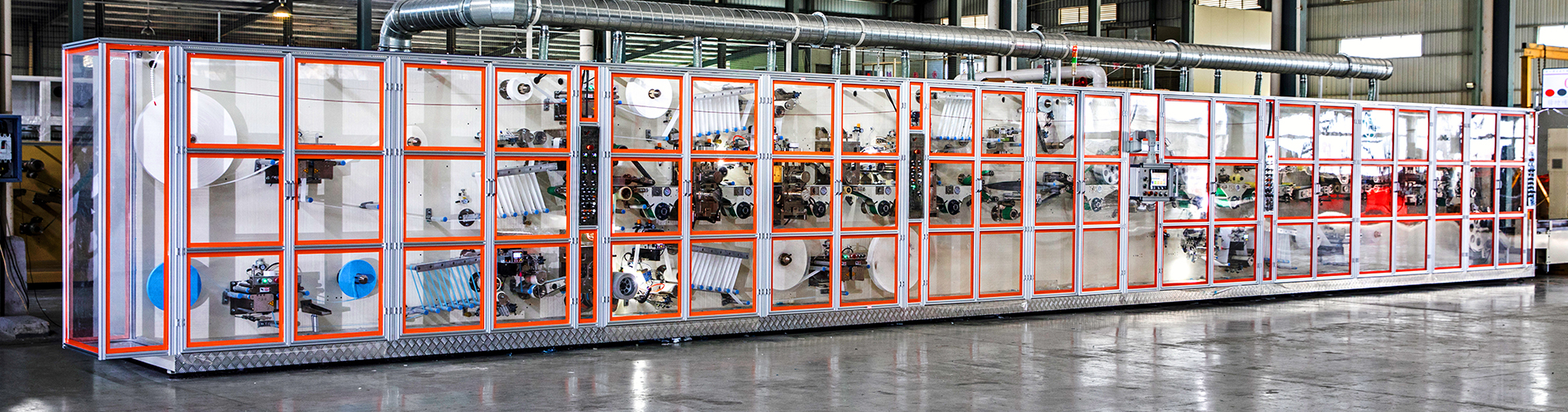

At the core of a modern diaper machine lies advanced technology that drives its performance. Key components include PLC (Programmable Logic Controller) control systems, full servo motors, and modular designs—features that set top-tier diaper production machines apart. The PLC control system acts as the "brain" of the machine, allowing precise programming and real-time adjustment of production parameters such as speed, material placement, and product dimensions. This ensures each diaper meets strict quality standards without manual intervention. Full servo motors, meanwhile, deliver exceptional precision and speed, powering critical processes like cutting, folding, and bonding with minimal vibration or error.

The modular design of leading diaper machines is another game-changer for manufacturers. Unlike traditional integrated machines, modular systems break down the production process into independent units—such as core formation, top sheet lamination, elastic application, and packaging. This design not only simplifies maintenance and repairs (technicians can address specific modules without halting the entire line) but also allows for easy upgrades. As market demands evolve—whether for eco-friendly materials, thicker cores, or specialized designs—manufacturers can modify or add modules to their diaper production machine instead of investing in a brand-new system.

So, how does a diaper machine actually work? The process begins with raw material feeding: non-woven fabrics, absorbent cores, elastic threads, and waterproof films are loaded into designated stations. Guided by the PLC system, the machine first cuts the non-woven fabric into the base shape of the diaper. Next, the absorbent core—often made of fluff pulp and superabsorbent polymers—is placed precisely on the base layer. Elastic threads are then attached to the leg and waist areas to ensure a snug fit, by lamination of the top sheet (for softness) and bottom sheet (for leak protection). Finally, the finished diapers are cut, folded, and packaged into bundles, ready for distribution.

A high-quality diaper production machine also boasts impressive production speed, with top models capable of manufacturing hundreds of diapers per minute. This efficiency, combined with the reliability of PLC control and servo motors, makes these machines indispensable for hygiene product manufacturers looking to scale their operations and meet market demands. Whether producing baby diapers for newborns or adult diapers for seniors, a well-designed diaper machine ensures consistent quality, cost-effectiveness, and flexibility—key factors for success in the competitive hygiene product industry.

Categories

Latest blog

© Copyright: QuanZhou XingYuan Machinery Manufacture Co.,Ltd All Rights Reserved.

IPv6 network supported