What’s a Diaper Machine’s Lifespan?

When investing in diaper production equipment, one key question looms: how long will the machine last? The lifespan of a diaper machine typically ranges from 10 to 15 years, but this figure hinges on three critical factors: build quality, maintenance practices, and technological adaptability.

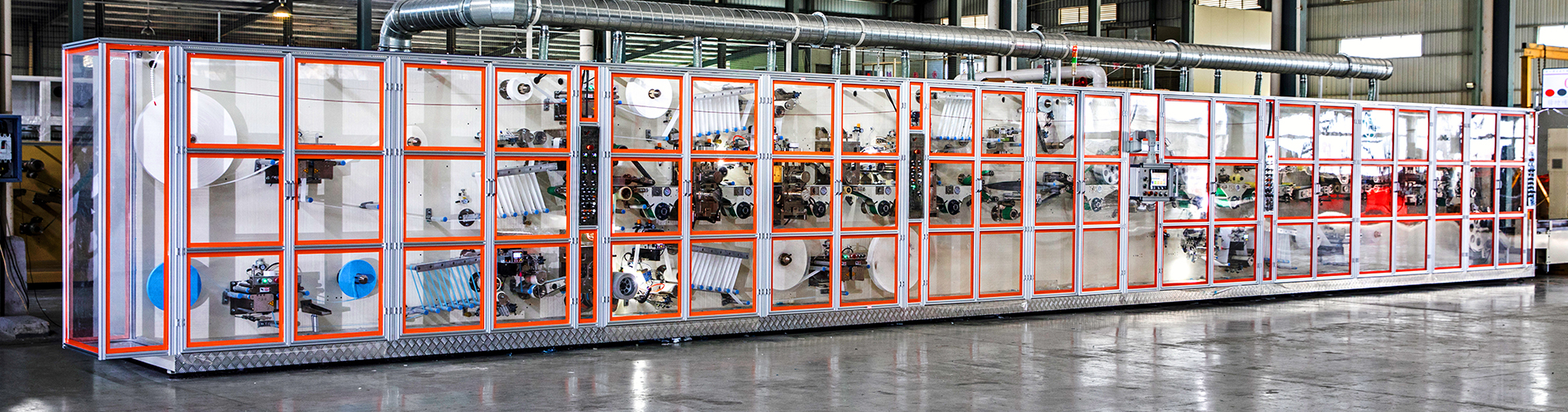

At the core of longevity lies the machine’s design and components. Models equipped with PLC control systems and full servo motors tend to outlast traditional alternatives. These precision parts minimize wear and tear by ensuring smooth, consistent operation—even at high production speeds. Modular design further extends lifespan: instead of replacing entire units when components age, operators can swap individual modules, reducing downtime and replacement costs.

Proactive maintenance is non-negotiable for maximizing lifespan. Daily checks of servo motor performance and PLC system calibrations prevent minor issues from escalating. Regular lubrication of moving parts, cleaning of product contact areas, and scheduled inspections of modular components are simple steps that pay off. Neglecting these tasks can cut a machine’s life short by 3 to 5 years.

Technological adaptability also plays a role. As consumer demands shift—for example, towards more absorbent diapers or sustainable materials—machines need upgrades. Modular designs shine here: they allow easy integration of new modules without overhauling the entire system. This adaptability ensures the machine remains relevant, avoiding premature obsolescence.

In short, a well-designed, well-maintained diaper machine is a long-term investment. Our PLC-controlled, full servo motor diaper machines with modular construction are engineered for durability. With proper care, they deliver reliable performance for over a decade, keeping your production line efficient and profitable.

Categories

Latest blog

© Copyright: QuanZhou XingYuan Machinery Manufacture Co.,Ltd All Rights Reserved.

IPv6 network supported