How Modular Design & Full-Servo Tech Boost Diaper Production

For diaper manufacturers, balancing production speed, flexibility, and product quality is a constant challenge. One clients recently overcame this hurdle, achieving a 40% output increase, thanks to two key innovations: modular design and full-servo technology.

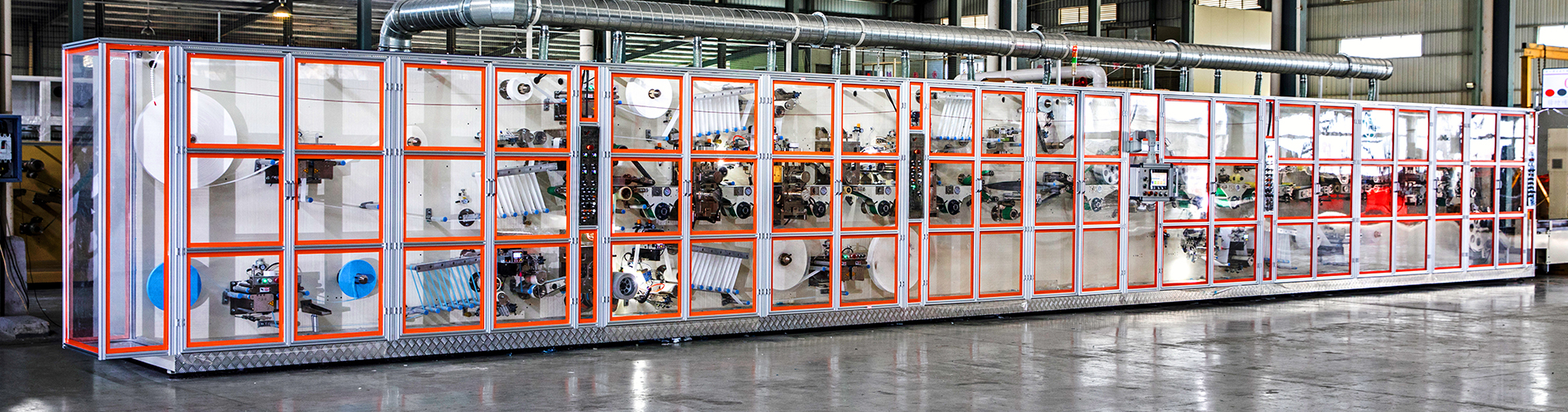

Modular design transforms production lines from rigid systems into adaptable setups. Each core component—from forming units to cutting modules—works independently while integrating seamlessly. When the client needed to switch between baby diaper sizes , reconfiguring the line took hours instead of days. This agility eliminated downtime bottlenecks, a major drag on previous efficiency.

Paired with modularity, full-servo technology elevated precision and speed. Unlike traditional mechanical systems with fixed motions, servo motors adjust in real time, optimizing material tension, folding accuracy, and cutting timing. This reduced material waste and minimized defective products, which previously required manual sorting and slowed output.

The combined impact was striking. The client’s production speed jumped from 500pcs/min to 700pcs/min units. Their ability to handle orders for improved, opening new market opportunities.

In an industry where demand fluctuates and product diversity is key, modular design and full-servo technology aren’t just upgrades—they’re game-changers. This client’s success story proves that smart engineering can turn production constraints into growth drivers.

Categories

Latest blog

© Copyright: QuanZhou XingYuan Machinery Manufacture Co.,Ltd All Rights Reserved.

IPv6 network supported