Elevate Your Diaper Production with Advanced Baby Diaper Machine Technology

In the fast-paced world of hygiene product manufacturing, efficiency, reliability, and flexibility are the keys to staying ahead of the competition. For businesses looking to scale their baby diaper production, investing in a high-performance Baby diaper machine is no longer an option—it’s a necessity. Our company’s flagship Baby diaper machine is engineered to meet the evolving demands of modern production lines, combining cutting-edge technology with user-centric design to deliver consistent results and maximum uptime.

At the heart of our Baby diaper machine lies a full servo control system, which sets it apart from traditional equipment. Unlike conventional machines that rely on mechanical transmission, full servo technology ensures precise synchronization of every component—from material feeding to cutting and folding. This precision translates to fewer product defects, uniform diaper sizes, and the ability to handle a wide range of raw materials, including ultra-soft nonwovens and high-absorbency cores. Whether you’re producing newborn-sized diapers or larger variants, the servo system adapts seamlessly, maintaining quality even at high production speeds.

Complementing the servo system is our integrated PLC (Programmable Logic Controller) technology, which simplifies operation and enhances process visibility. The user-friendly PLC interface allows operators to set production parameters, monitor real-time performance, and troubleshoot issues with just a few clicks. This not only reduces the learning curve for new staff but also minimizes human error—critical for maintaining consistent output in 24/7 production environments. With remote monitoring capabilities, managers can even track machine performance from off-site, ensuring timely adjustments and minimizing downtime.

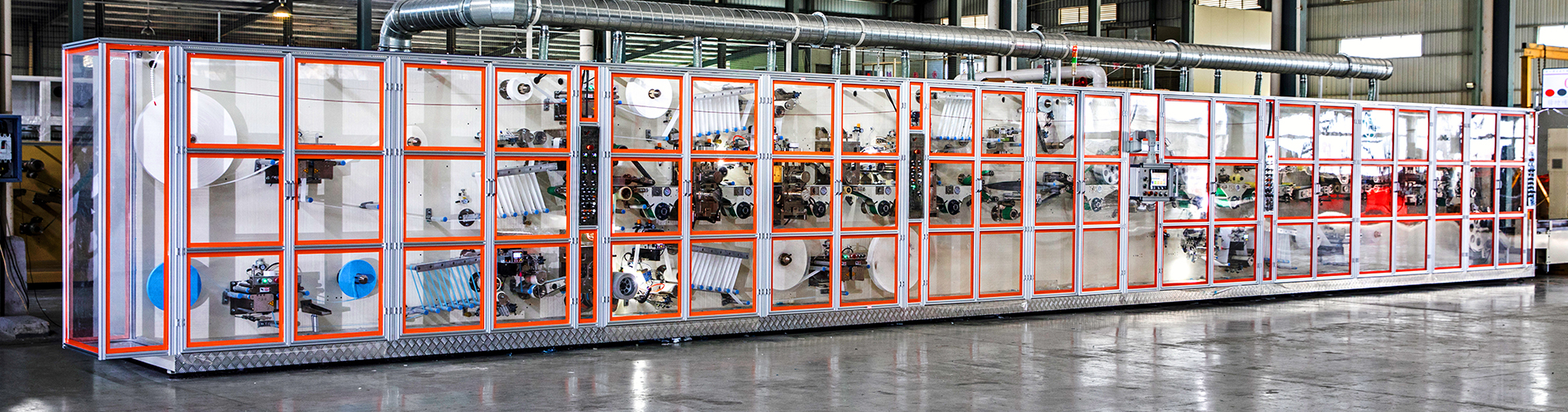

Another standout feature of our Baby diaper machine is its modular design, a game-changer for daily maintenance and future upgrades. Traditional machines often require extensive disassembly to repair or replace parts, leading to long production halts. Our modular structure breaks the machine into independent units—such as the core forming module or elastic application module—allowing technicians to access and service components quickly. This design also means upgrading your machine is hassle-free: when you need to add new functions (like wetness indicator integration) or increase capacity, you can simply replace or add modules instead of investing in a brand-new machine.

For businesses in the baby diaper industry, every minute of downtime and every defective product impacts the bottom line. Our Baby diaper machine addresses these challenges head-on, with technology that boosts efficiency, ensures quality, and grows with your business. Whether you’re a small manufacturer looking to expand or a large enterprise aiming to optimize existing lines, our equipment is designed to deliver long-term value.

Ready to take your baby diaper production to the next level? Explore our Baby diaper machine range today and discover how innovation can transform your operations.

Categories

Latest blog

© Copyright: QuanZhou XingYuan Machinery Manufacture Co.,Ltd All Rights Reserved.

IPv6 network supported