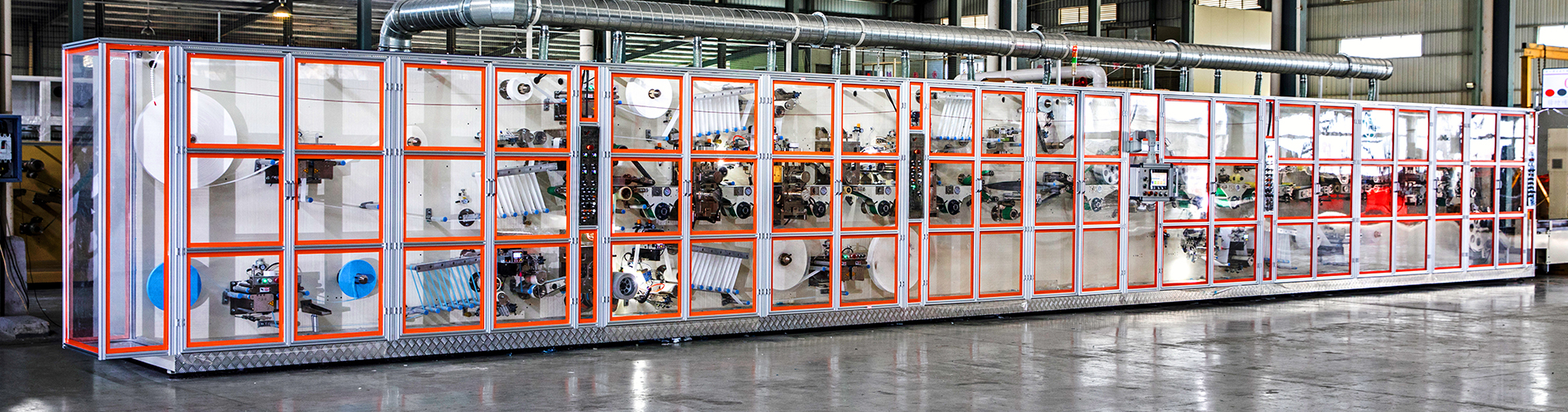

A diaper production line refers to a series of interconnected and coordinated equipment and processes involved in the complete manufacturing process, from raw materials to the final product. It is an automated system designed to efficiently produce high-quality diapers that meet the required standards.

A complete diaper production line typically includes the following equipment:

Raw Material Processing Equipment:

Material Unwinding Machine: This machine unwinds the raw material rolls and feeds them into the subsequent production line.

Cutting Machine: It cuts the unwound materials into appropriate sizes for diaper production.

Core Production Equipment:

Super Absorbent Polymer (SAP) Addition Machine: It uniformly adds SAP to the absorbent paper or pulp to enhance the diaper's absorption performance.

Absorbent Paper Layer Manufacturing Machine: It mixes and forms the absorbent paper or pulp with SAP to create the absorbent core, which is a crucial part of the diaper.

Top Sheet Manufacturing Equipment:

Top Sheet Manufacturing Machine: It produces nonwoven fabric layers, such as thermally bonded fibers, to serve as the top sheet of the diaper.

Adhesive Machine: It bonds the nonwoven fabric layer with other components, such as the absorbent core and backsheet, to form the diaper's top sheet.

Backsheet Manufacturing Equipment:

Backsheet Unwinding Machine: It unwinds the backsheet roll and feeds it into subsequent processes.

Backsheet Cutting Machine: It cuts the unwound backsheet into appropriate segments for diaper production.

Cutting and Shaping Equipment:

Frontal Waistband Cutting Machine: It cuts the top sheet and backsheet according to the design requirements to shape the diaper's frontal waistband.

Rear Waistband Cutting Machine: It cuts the top sheet and backsheet according to the design requirements to shape the diaper's rear waistband.

Trimming Machine: It trims the overall shape of the diaper and completes other detailed shaping.

Elastic Bands and Fastening Attachment Equipment:

Elastic Band Positioning Machine: It positions the elastic bands in the leg areas of the diaper.

Attachment Installation Machine: It installs other attachments, such as tapes and labels, onto the diaper.

Inspection and Packaging Equipment:

Inspection Machines: These machines are used to inspect the quality and performance of diapers, such as absorbency and leakage prevention. They can perform automated testing and sorting to ensure consistent diaper quality.

Packaging Machines: They package the finished diapers, typically using plastic film for individual or combination packaging. Packaging machines can automate the packaging process, improving production efficiency and product hygiene.

Testing and Quality Control Equipment:

Quality Control Systems: These systems monitor key indicators during the diaper production process, such as absorbency, size, and appearance. They utilize sensors, cameras, and computer software to ensure the produced diapers meet the quality standards.

Data Collection and Analysis Equipment: These devices collect and analyze data during the production process to improve efficiency and quality. They record key parameters and metrics, assisting production line managers in making decisions and adjustments.

Waste Handling Equipment:

Waste Recycling Machines: They collect and process waste and by-products generated during the production process. These machines can separate, compress, or recycle waste materials to minimize waste and environmental impact.

Control Systems and Automation Equipment:

Programmable Logic Controllers (PLCs): They control the entire diaper production line, including coordinating the actions of various equipment and adjusting parameters. PLCs enable automated production processes, enhancing production efficiency and consistency.

Conveyor Belts and Conveying Systems: They are used to transport and transfer raw materials and semi-finished products between different stages of the production line. These systems improve production efficiency and ensure a seamless workflow.