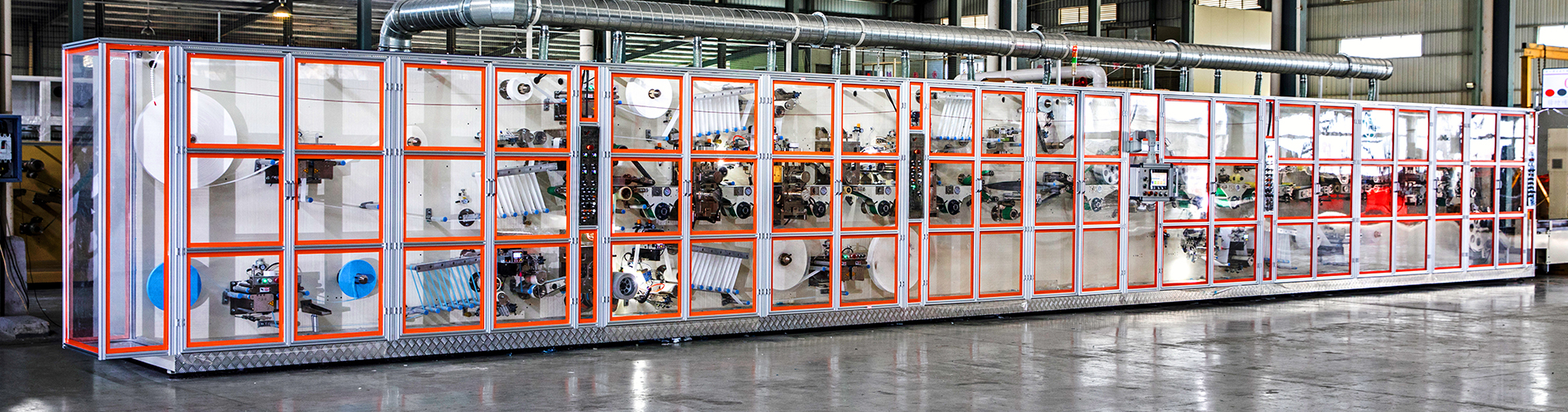

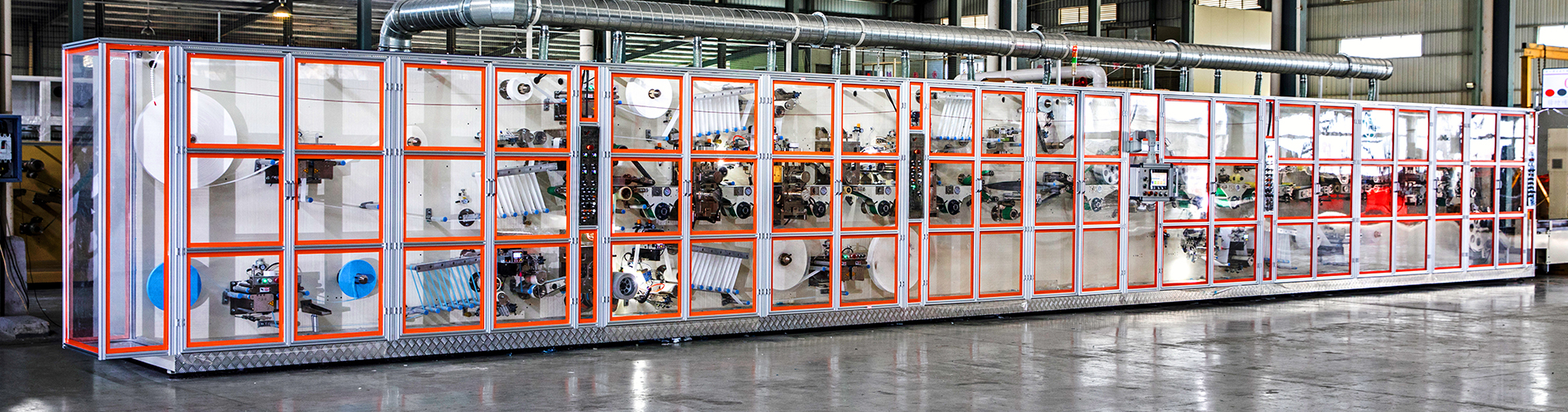

Disposable Medical Incontinence Underpad Machine Line

Item No.:

DNW-UP033Payment:

30% T/T Deposit,70% Balance Before ShippingProduct origin:

ChinaColor:

CustomizedShipping port:

XiamenLead Time:

About 180daysDisposable Medical Incontinence Underpad Machine Line

Feature:

Feature:

1. The overall design of the mechanical structure is simple and reasonable, easy to operate and adjust.

2. The closed longitudinal sealing device is adopted to make the longitudinal sealing more stable, firm and stable.

3. High speed transverse sealing device, high sealing and cutting speed, clear and beautiful mesh.

4. It has the function of automatic positioning and parking (preventing film burning).

5. Special products can be equipped with safety clutch devices to protect packaged goods.

Company Information:

JHC Group is dedicated to the Hygiene industry for decades, have invested in 7 factories and companies to offer the turnkey solution for the diaper/sanitary napkin/underpad & pet pad/ manufactures by the full supply chain of machines, raw materials, and finished products.

We occupy 60000+M2 factory land for manufacturing of Machinery, Non-woven fabrics, PE films, Frontal and side tapes, diapers, sanitary napkins, and underpads, achieved 128 Million USD sales volume in 2020. Our diaper/sanitary napkin/underpad machines have been selected by China listed company "YiYi", "Greenleaf" after serious investigation and comparison by their professional team among all machine factories. All our machines have CE & UL Certification and we passed the quality management system ISO9001.

We stick to the customer-centric policy and focus on long-term cooperation with every partner. We treat our quality and customer demand as the first priority and gain full satisfaction from all buyers because of premium quality, considerate pre & after service, easy operating and maintenance, high speed and stable working status, with our exquisite design and technology innovation, our machines are the most cost-effective solution all over the worldwide factories.

We warmly welcome you to come to visit us any time and assure the most lucrative collaboration will be concluded.

Why choose us?

1. Professional & Reliable:

We have our own factory, specialized in a wide range of disposable products making machine with the good performance in the leading field. Backed by experienced and qualified technology team of experts. We can provide high quality machines at cost effective prices, lead customer to success.

2. Efficient Communication:

Our experienced sales team offer with factory price, and direct sales service, reliable after-sale-service at professional and most efficient manner, make communication much more easier.

3. Constantly Evolving:

The qualty of the machines are carefully and strictly controlled by our inspection engineers, guarantee customer can get the right function machine and spare parts.

FAQ:

1. What is your manufacture date ?

The manufacture date is 120 days after deposit receipt.

2. What is your order payment terms ?

30% deposit in advance and 70% balance before shipment.

3. Can you send us samples of the finally priduct ?

Yes, free samples can be sent out, the freight charge is paid by you.

(1). You can provide your a/c like DHL or FEDEX or TNT

(2). You can call your courier to pick up at our office.

(3). You can pay us the express charge by western union or T/T.

Hot Tags :

Previous :

High Production Efficiency Underpad Machine Pet Pad MachineNext :

Quality Assurance Puppy Under Bed Pads MachineIf you have questions or suggestions, please leave us a message,we will reply you as soon as we can!

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Automatic baby diaper making machine adult diapers making machine

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

I Shape T Shape Full Elastic Baby Diapers Making Machine

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Low Scrap Rate Configure Tension Uncoiling System Super Conductive Layer Sanitary Napkin Machine

Efficient Automation Pre Sales and After-sales Service Leak Proof Comfort Sanitary Napkin Machine

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Single-axle gear,imported timing belt,key position adopt the imported bearing. Product size: Daytime use: 240mm Night use: 285mm(Customized) Control system: PLC programming control,HMI operation.

DNW FULL SERVO PET PADS UNDERPDS PRODUCTION LINE 300M/min

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Drive system: 3-Shaft Mechanical Drive,Semi-servo,Full servo can be choose by customer's requirement Product size: S: 390*280 M: 450*320 L: 500*320 XL: 525*330 Control system: PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

High Efficiency And Energy Saving Baby Diaper Packing Machine

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

High Accuracy Double Layer Enclosure Leakage Proof Small Scale Semi Auto Baby Diapers Machine

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Full servo automatic adult diaper machine with CE certification

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Automatic Full Servo baby diaper making machine (600pcs per minute)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: 3-Shaft Mechanical Drive,Semi-servo,Full servo can be choose by customer's requirement Product size: S: 390*280 M: 450*320 L: 500*320 XL: 525*330 Control system: PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Drive system: Full servo drive. Using import conveyor and timing belt. Important part using import bearing. Product size: Daytime use: 240mm Night use: 285mm(Customized) Control system: PLC programming control,HMI operation.

Drive system: Full servo drive. Using import conveyor and timing belt. Important part using import bearing. Product size: Daytime use: 240mm Night use: 285mm(Customized) Control system: PLC programming control,HMI operation.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Integrated Equipment Easy to Use Inlet Bearing Rotation disposable Strong Absorption Disposable Under Pad Making Machine

FULL SERVO THREE-PIECES SHAPE PULL-UP PANTS PRODUCTION LINE

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: 3-Shaft Mechanical Drive,Semi-servo,Full servo can be choose by customer's requirement Product size: S: 390*280 M: 450*320 L: 500*320 XL: 525*330 Control system: PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Fully Automated Baby Diaper Machine Plastic Diapers Machine Customized Baby Diaper Making Machine

Drive system: Full-servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Full servo disposable bed pad making machine CE & ISO approved

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Long Service Life Leak Proof Comfort Adult Diapers Machine With Configure Tension Uncoiling System

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Brand New CE Certificated High Quality Wood Pulp Comfortable Environmental Protection Disposable Sanitary Napkin Machine

Full servo men woman adult diaper making machine

High Efficiency and Energy Saving Baby Diaper Making Machine

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Economic type classic I shape baby diaper machine Drive system:Fully automatic,Semi-servo,Full servo can be choose by customer's requirement Product size: 4 size,S-M-L-XL Control system:PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Wholesale Manufacturing Sanitary Pad Making Machine

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Double Layer Enclosure Leakage Proof Adult Diapers Machine With Configure Tension Uncoiling System. PLC control system,operating on the touch screen, configure HDTV monitor.

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Fast Speed Used Baby Diaper Machine Drive system:Fully automatic,Semi-servo,Full servo can be choose by customer's requirement Product size: 4 size,S-M-L-XL Control system:PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: 3-Shaft Mechanical Drive,Semi-servo,Full servo can be choose by customer's requirement Product size: S: 390*280 M: 450*320 L: 500*320 XL: 525*330 Control system: PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Intelligent Control After Sales Warranty PLC Touch Screen Control Sanitary Napkin Machine

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Full servo I type with online full elastic waistband and s cut velcro side tape baby diaper making machine Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: 3-Shaft Mechanical Drive,Semi-servo,Full servo can be choose by customer's requirement Product size: S: 390*280 M: 450*320 L: 500*320 XL: 525*330 Control system: PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Drive system: 3-Shaft Mechanical Drive,Semi-servo,Full servo can be choose by customer's requirement Product size: S: 390*280 M: 450*320 L: 500*320 XL: 525*330 Control system: PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Automatic adult diaper making machine

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Door to Door Installation and Commissioning Baby Diaper Machine With Configure Tension Uncoiling System

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: 3-Shaft Mechanical Drive,Semi-servo,Full servo can be choose by customer's requirement Product size: S: 390*280 M: 450*320 L: 500*320 XL: 525*330 Control system: PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

High Production Efficiency Super Conductive Layer Disposable Sanitary Napkin Machine

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Pre Sales and After-sales Service High Production Efficiency German Made Under Pad Machines

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Drive system: Single-axle gear,imported timing belt,key position adopt the imported bearing. Product size: Daytime use: 240mm Night use: 285mm(Customized) Control system: PLC programming control,HMI operation.

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Double Layer Enclosure Leakage Proof Adult Diapers Machine With Configure Tension Uncoiling System

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Full Automatic Fast-Easy Pakage Sanitary Napkin Production Line

FULL SERVO STRIP BAG SANITARY NAPKIN PRODUCTION LINE FOR FACTORY

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

REUSABLE FULL SERVO ADULT DIAPER PRODUCTION LINE

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Automatic Sanitary Pads Manufacturing Machine

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Variable Frequency Control Motor Fast Speed High Degree of Automation Baby Diaper Machine

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Drive system: 3-Shaft Mechanical Drive,Semi-servo, Full servo can be choose by customer's requirement Product size: S: 390*320 M: 450*320 L: 485*330 XL: 520*330 Control system: PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization. Tension System: Top tissue paper, cotton core(SAP), bottom toiletpaper, top sheet,PE film. A&B shaft unwindingbyinverter motor. Safety System: It has safety device on theoperating side, matched withurgent stop switch.High audio fanuses sound insulation or silencer.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

DNW Adult Diaper Production Line

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: 3-Shaft Mechanical Drive,Semi-servo,Full servo can be choose by customer's requirement Product size: S: 390*280 M: 450*320 L: 500*320 XL: 525*330 Control system: PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Servo Drive Easy to change size Full Automatic Adult Diaper Making Machine operating on the touch screen PLC control system

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Full-servo Full Elastic Waistband Baby Diaper Making Machine

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: Servo Drive(Easy to change size),timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product size: 155,180,190mm Optional: Full automatic packing machine(stacker +bagger) Economical type-semi servo

Drive system: Single-axle gear,imported timing belt,key position adopt the imported bearing. Product size: Daytime use: 240mm Night use: 285mm(Customized) Control system: PLC programming control,HMI operation.

Drive system: 3-Shaft Mechanical Drive,Semi-servo,Full servo can be choose by customer's requirement Product size: S: 390*280 M: 450*320 L: 500*320 XL: 525*330 Control system: PLC control system,operating on the touch screen,man-machine interface,match with a LED digital display to control the production by pattern digization.

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Hygienic adult diapers diaper production equipment

CE and UL Certificated Stable Production Speed Professional After-sales Service Comfortable Fitting OEM Disposable Sanitary Napkin Machine China Supplier.

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Full Servo Pull Up Baby Diaper Making Machine Quick Details Applicable Industries: Manufacturing Plant, Machinery Repair Shops Condition: New Product Type: Paper Product Making Machinery Processing Type: Laminating Machine Place of Origin: Fujian Brand Name: DNW

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

HIGH QUALITY FULL SERVO STRIP BAG SANITARY NAPKIN PRODUCTION LINE

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Single-axle gear,imported timing belt,key position adopt the imported bearing. Product size: Daytime use: 240mm Night use: 285mm(Customized) Control system: PLC programming control,HMI operation.

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Hot Selling High Quality Professional Customized Multilayer Leak Proof Lowest Price Baby Diaper Making Machine.

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

High Quality Assurance Save Time and Effort Strong Absorption Women's Sanitary Napkin Production Machine

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Product size: 60*60cm,60*90cm,etc Optional: Full automatic packing machine(stacker+bagger) Optional: Economical type-semi servo

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Drive system: Full servo drive,digital size change,ensure run synchronized at full process.The frontal tape and back sheet using servo positioning cutting to ensure pattern consistent with the phase. Product size: S: 390*320 M: 450*320 L: 500*330 XL: 525*330 Control system: PLC control,HMI operation,LED digital display,graphic digitization control.

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface

Product structure: Tissue paper, sap paper, topsheet nonwoven, double wing nonwoven(3pcs),ADL, backsheet, back&wings, release paper, packing film. Tension system: Tension unwinding equipped, constant tension control with buffer system, automatic web guide system. The unwinding system ensure materials stable working at full speed splice, minimize the impact on materials tension force, to reduce the time of stop machine. Drive system: Full servo driven, imported timing blet, key position adopt with the imported bearing. Safety system: It has safety device on the operating side, matched with urgent stop switch, high audio fan uses sound insulation or silencer. Materials corrective system: Germany BST automatic web guide system(optional)

Disposable Semi Automatic Baby Adult Diaper & Women Sanitary Napkin Packing Machine Price

Drive system: Timing belt and flat belt are imported products,and all the key parts are imported bearings. Product size: M: 680*450 L: 800*650 XL: 950*760 Control system: PLC control system,operating on the touch screen,man-machine interface