Categories

New Products

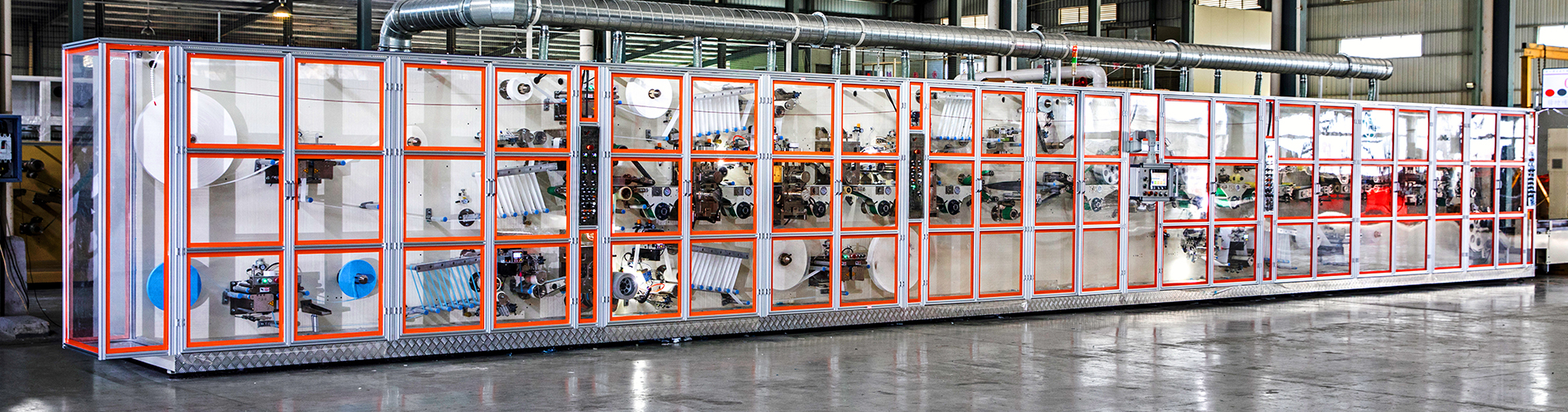

High Production Efficiency Adult Diapers Making Machine South Africa Read more

After Sales Warranty Sanitary Napkin Making Machine Read more

Four Seasons Available Smooth Operation Medical Under Pad Machine Read more

Economical and Practical Sanitary Napkin Production Machine Read more

Low Price Famous Brand Adult Diapers Making Machine South Africa Read more

Low Price Strong Absorption Disposable Baby Diaper Making Machine Read more

Door to Door Installation and Commissioning Women's Sanitary Napkin Machine Read more

International Brand Correction System Disposable Under Pad Making Machine Read more

© Copyright: QuanZhou XingYuan Machinery Manufacture Co.,Ltd All Rights Reserved.

IPv6 network supported